How 3D Printing FDM Can Revolutionize Your Business

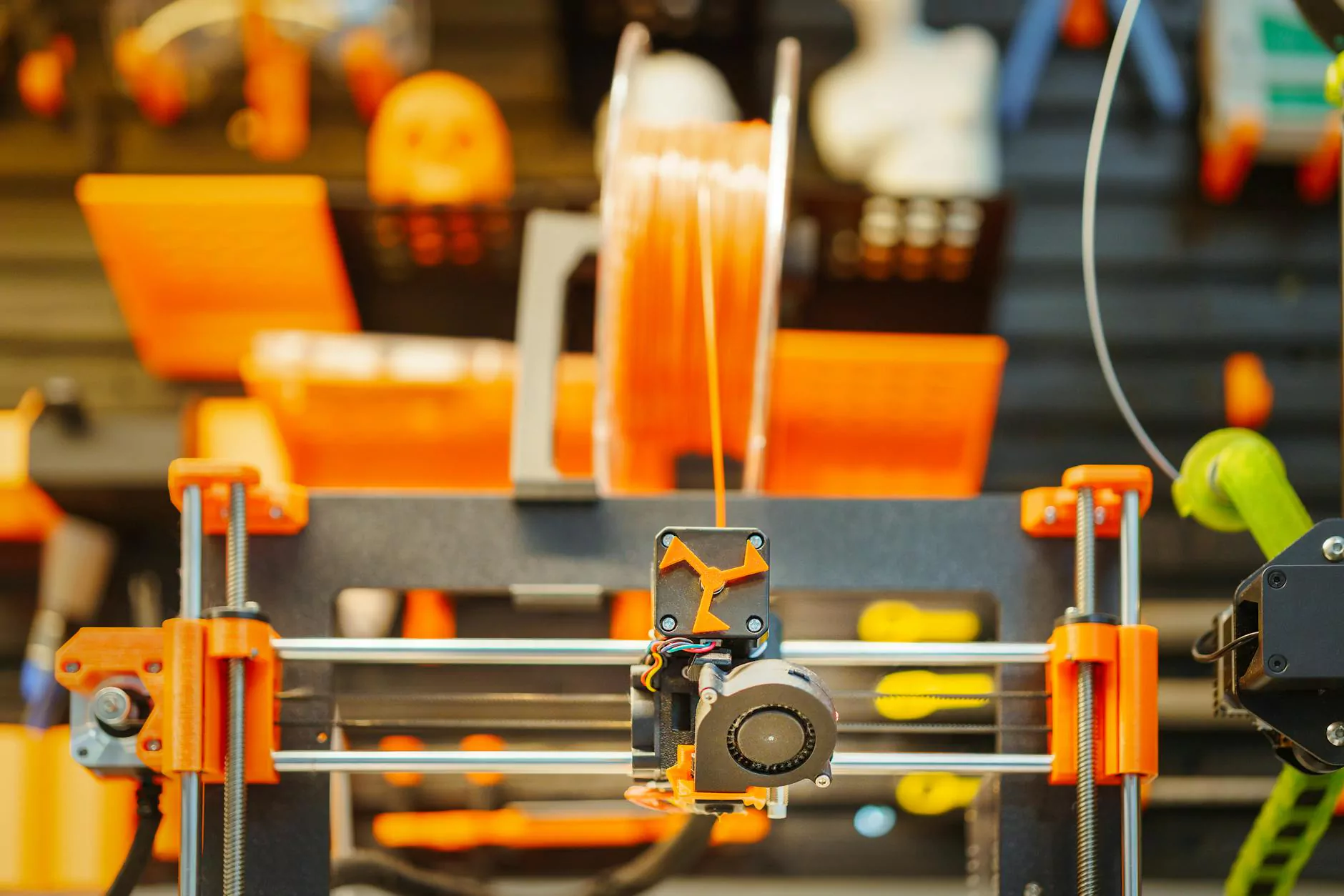

Understanding the Power of 3D Printing FDM

In today's fast-paced and competitive business world, finding innovative solutions that streamline operations and enhance productivity is key. One such game-changing technology that has gained significant traction is 3D printing FDM (Fused Deposition Modeling). QuickParts, a leading provider in the industry, offers a comprehensive range of 3D printing services and solutions tailored to meet your business needs.

Exploring the Applications of 3D Printing FDM

3D printing FDM provides endless possibilities for businesses across various industries. Let's delve deeper into some of the popular applications:

- Prototyping: With 3D printing FDM, companies can rapidly create prototypes in a cost-effective manner. Whether you're in the automotive, aerospace, or consumer goods industry, producing accurate prototypes with intricate details is now a breeze.

- Manufacturing Aids: Enhance your manufacturing processes by utilizing 3D printing FDM to create customized jigs, fixtures, and tooling. These aids can improve efficiency, reduce costs, and optimize production workflows.

- Product Development: Innovate and iterate faster by incorporating 3D printing FDM into your product development cycle. Iterate designs, test concepts, and refine prototypes at an accelerated pace, giving you a competitive edge in the market.

- Education and Research: 3D printing FDM plays a pivotal role in academic institutions and research facilities where practical demonstrations and tangible models are crucial for understanding complex concepts.

The Advantages of 3D Printing FDM

Embracing 3D printing FDM offers numerous advantages that give your business an edge:

- Cost-Efficiency: Traditional manufacturing methods often come with high costs, especially for custom or low-volume production. 3D printing FDM eliminates the need for expensive tooling and enables cost-effective production.

- Time-Saving: Speed is often paramount in today's competitive landscape. 3D printing FDM allows for rapid production of prototypes and functional parts, slashing lead times and accelerating product development.

- Design Freedom: Unleash your creativity with 3D printing FDM's exceptional design freedom. Complex geometries, intricate details, and organic shapes can all be achieved without the design restrictions of traditional manufacturing techniques.

- Minimal Material Waste: Unlike subtractive manufacturing methods, 3D printing FDM only uses the necessary amount of material, resulting in minimal waste and reduced environmental impact.

- Flexibility and Customization: Tailor your products to specific customer requirements and easily accommodate last-minute design changes with the flexibility offered by 3D printing FDM.

Best Practices for Implementing 3D Printing FDM in Your Workflow

To fully leverage the power of 3D printing FDM, implementing best practices is crucial. Here are some recommendations to ensure you maximize the benefits:

Quality Design Files

Optimize your design files for 3D printing FDM by following industry-accepted standards, such as using correct file formats, creating watertight models, and ensuring appropriate wall thicknesses. QuickParts' experienced team can guide you through this process.

Material Selection

Understanding the characteristics of different FDM materials is essential for choosing the right one for your specific application. QuickParts offers a wide range of materials, each with its unique properties and performance capabilities.

Print Parameters

Accurate print parameters are critical for achieving high-quality results. Work closely with QuickParts to fine-tune printing parameters like layer height, infill density, and support structures to ensure optimal part strength and surface finish.

Post-Processing Techniques

Explore various post-processing techniques and finishes that can enhance the aesthetics and functionality of your 3D printed parts. QuickParts' experts can advise you on sanding, painting, or even applying specialized coatings to achieve the desired outcome.

Continued Innovation

Stay updated with the latest advancements in 3D printing FDM technology and explore new applications as they emerge. QuickParts' commitment to research and development ensures access to cutting-edge solutions.

Partner with QuickParts for 3D Printing FDM Excellence

QuickParts is your trusted partner in leveraging the full potential of 3D printing FDM for your business. With an unparalleled range of services, state-of-the-art equipment, and a team of seasoned professionals, we deliver exceptional results that propel your company forward.

Experience the competitive advantage of 3D printing FDM with QuickParts - a winning combination that revolutionizes your business.